Manufacturing

Process

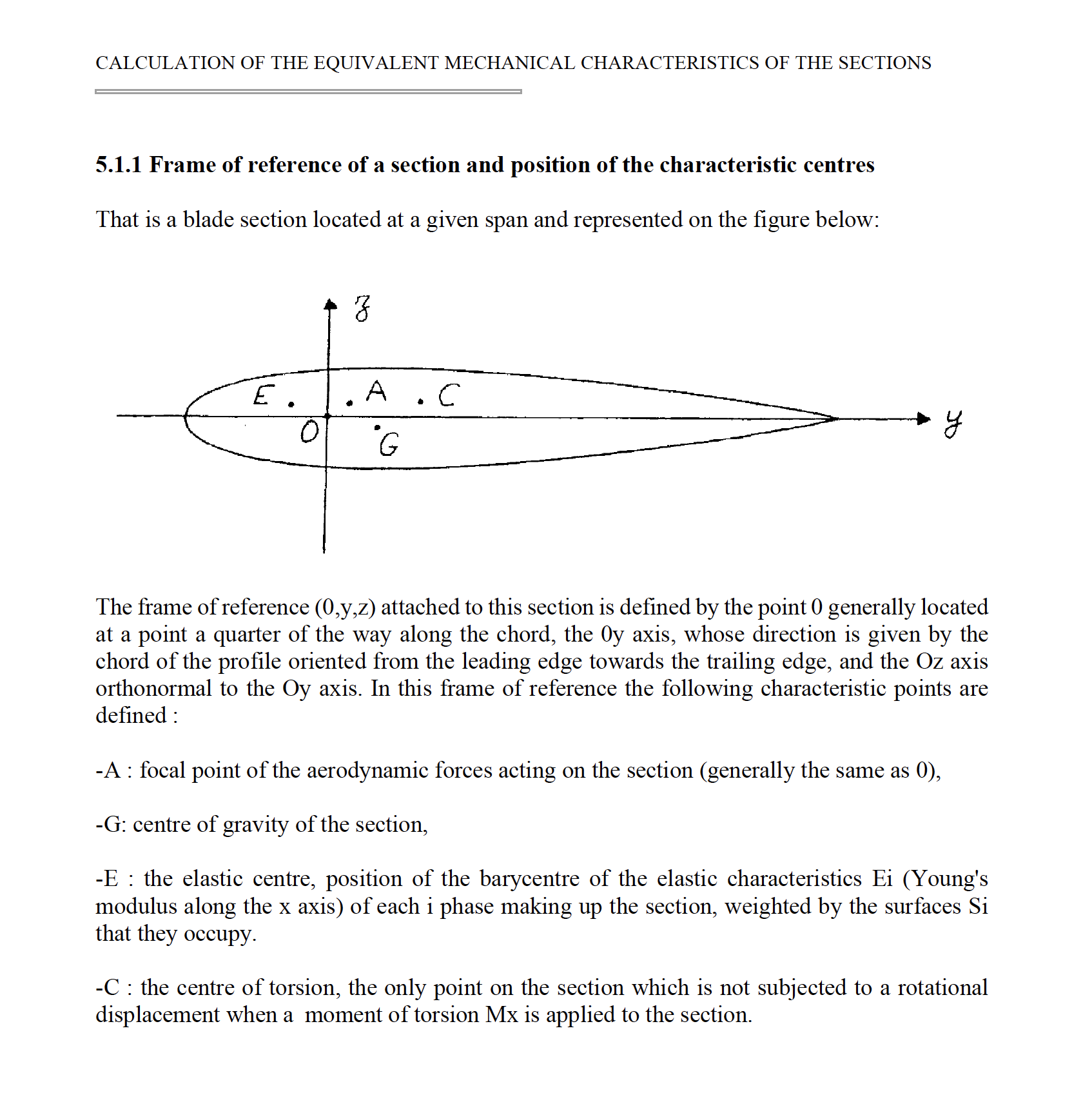

One of the key point, is the relation between the structural construction of the blade and noise origin

1.

The first point has to design a structural blade with an high own frequency (flap, lag and torsion) in order to influence some noise parameter sources

2.

The fiber placement with tipical angles, allowed a coupling flap and torsion resolving some ather noise parameters

Complete automatised production

Constant research

We proceed at new development in relationship with aeronautic laboratory secialised in acoustic problem

New airfoil

Vibrating tip

Influence of material memory

Vibrating excitation

etc…